Financial Benefits of Using 3D Printing in Small Businesses

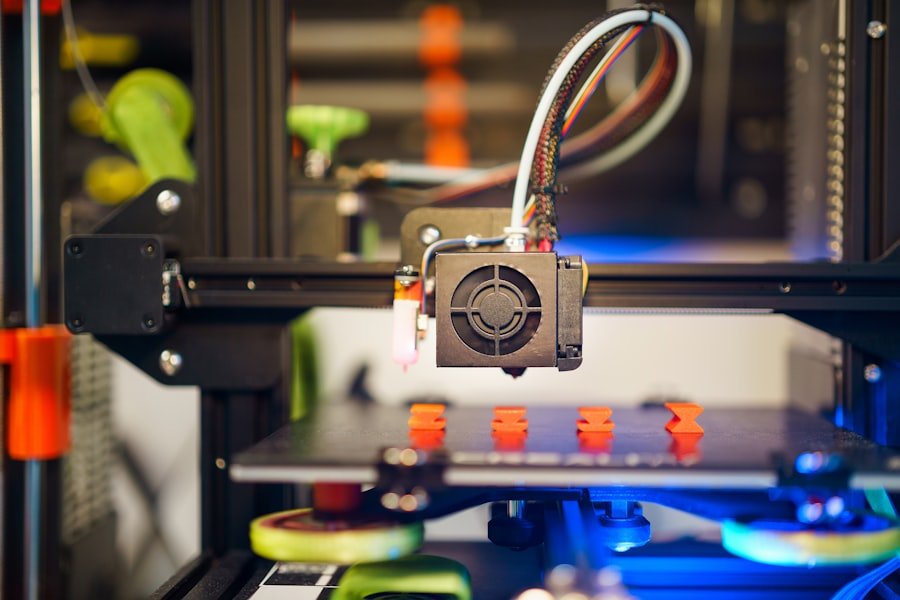

In today’s competitive business environment, cost savings are a top priority for companies looking to maximize their profits. Additive manufacturing, also known as 3D printing, has emerged as a significant innovation in this regard. Traditional manufacturing methods often involve high setup costs, especially for small production runs.

3D printing eliminates the need for expensive tooling and molds, resulting in substantial cost savings. 3D printing allows for the use of a wide range of materials, including plastics, metals, and ceramics, which can be more cost-effective than traditional manufacturing materials. This technology enables companies to reduce waste by producing only the exact amount of parts needed, minimizing excess inventory and storage costs.

The on-demand production model not only saves money but also reduces the environmental impact of manufacturing. Furthermore, 3D printing offers flexibility in design and production, allowing for rapid prototyping and customization without significant additional costs. This can lead to faster product development cycles and improved time-to-market for new products.

The cost savings associated with 3D printing make it an attractive option for businesses looking to streamline their production processes and improve their bottom line. As the technology continues to advance, it is likely to play an increasingly important role in manufacturing across various industries.

Customization and Personalization

Unparalleled Customization and Personalization

One of the most significant advantages of 3D printing is its ability to offer customization and personalization on a level that traditional manufacturing methods cannot match. With 3D printing, companies can easily create unique, one-of-a-kind products tailored to individual customer needs and preferences. This level of customization not only enhances the customer experience but also opens up new opportunities for product innovation and market differentiation.

Complex Geometries and Intricate Designs

Moreover, 3D printing allows for the creation of complex geometries and intricate designs that would be difficult or impossible to achieve with traditional manufacturing methods. This means that companies can offer highly detailed and specialized products that cater to niche markets or specific customer requirements.

Rapid Design Iterations and Product Refinement

Additionally, 3D printing enables rapid design iterations, allowing companies to quickly test and refine new product concepts based on customer feedback. This iterative approach to product development can lead to the creation of highly personalized and innovative products that resonate with consumers.

Rapid Prototyping

Rapid prototyping is another key benefit of 3D printing that has revolutionized the product development process for many companies. With traditional manufacturing methods, creating prototypes can be time-consuming and costly, often requiring specialized tooling and machining. However, 3D printing allows for the quick and cost-effective production of prototypes directly from digital designs.

This means that companies can rapidly iterate on their product concepts and bring new ideas to life in a matter of hours or days rather than weeks or months. Additionally, 3D printing enables the production of functional prototypes that closely resemble the final product in terms of form, fit, and function. This level of accuracy and detail allows companies to thoroughly test and validate their designs before moving into full-scale production, reducing the risk of costly errors and design flaws down the line.

Furthermore, rapid prototyping with 3D printing empowers companies to explore new design possibilities and push the boundaries of innovation without being constrained by traditional manufacturing limitations. Moreover, 3D printing allows for the quick and cost-effective production of prototypes directly from digital designs. This means that companies can rapidly iterate on their product concepts and bring new ideas to life in a matter of hours or days rather than weeks or months.

Additionally, 3D printing enables the production of functional prototypes that closely resemble the final product in terms of form, fit, and function. This level of accuracy and detail allows companies to thoroughly test and validate their designs before moving into full-scale production, reducing the risk of costly errors and design flaws down the line. Furthermore, rapid prototyping with 3D printing empowers companies to explore new design possibilities and push the boundaries of innovation without being constrained by traditional manufacturing limitations.

Reduced Inventory Costs

Traditional manufacturing often requires companies to maintain large inventories of finished goods in anticipation of customer demand. This can tie up valuable capital and warehouse space while also increasing the risk of excess inventory and obsolescence. However, 3D printing enables on-demand production, allowing companies to produce parts and products only as they are needed.

This just-in-time manufacturing approach reduces the need for large inventories and minimizes the associated carrying costs. Furthermore, 3D printing supports distributed manufacturing models, where products can be produced closer to the point of consumption rather than being centralized in a single location. This can lead to further reductions in inventory costs by minimizing transportation and logistics expenses.

Additionally, 3D printing enables companies to quickly respond to changes in demand or market trends by adjusting their production schedules in real-time. This flexibility not only reduces inventory holding costs but also improves overall supply chain efficiency. On the other hand, 3D printing enables on-demand production, allowing companies to produce parts and products only as they are needed.

This just-in-time manufacturing approach reduces the need for large inventories and minimizes the associated carrying costs. Furthermore, 3D printing supports distributed manufacturing models, where products can be produced closer to the point of consumption rather than being centralized in a single location. This can lead to further reductions in inventory costs by minimizing transportation and logistics expenses.

Additionally, 3D printing enables companies to quickly respond to changes in demand or market trends by adjusting their production schedules in real-time. This flexibility not only reduces inventory holding costs but also improves overall supply chain efficiency.

On-Demand Production

The concept of on-demand production is a significant advantage offered by 3D printing technology. Unlike traditional manufacturing methods that require large production runs to be cost-effective, 3D printing allows for the economical production of small batch sizes or even individual items. This means that companies can respond quickly to customer orders without being constrained by minimum order quantities or long lead times.

Moreover, on-demand production with 3D printing enables companies to offer a wider range of products without incurring additional setup costs or tooling expenses. This flexibility allows businesses to cater to niche markets or create custom products tailored to specific customer needs. Additionally, on-demand production supports a more sustainable approach to manufacturing by reducing overproduction and minimizing excess inventory.

Furthermore, on-demand production with 3D printing enables companies to offer a wider range of products without incurring additional setup costs or tooling expenses. This flexibility allows businesses to cater to niche markets or create custom products tailored to specific customer needs. Additionally, on-demand production supports a more sustainable approach to manufacturing by reducing overproduction and minimizing excess inventory.

Competitive Advantage

Customization and Differentiation

By leveraging the customization capabilities of 3D printing, businesses can offer unique products that stand out in the market and appeal to discerning consumers.

Speed and Agility

Additionally, 3D printing enables companies to bring new products to market faster than ever before, giving them a first-mover advantage over competitors. The ability to rapidly prototype and iterate on designs allows businesses to stay ahead of trends and respond quickly to changing consumer preferences.

Innovative Product Design

Furthermore, 3D printing opens up new opportunities for product innovation by enabling the creation of complex geometries and novel designs that would be difficult or impossible to achieve with traditional manufacturing methods.

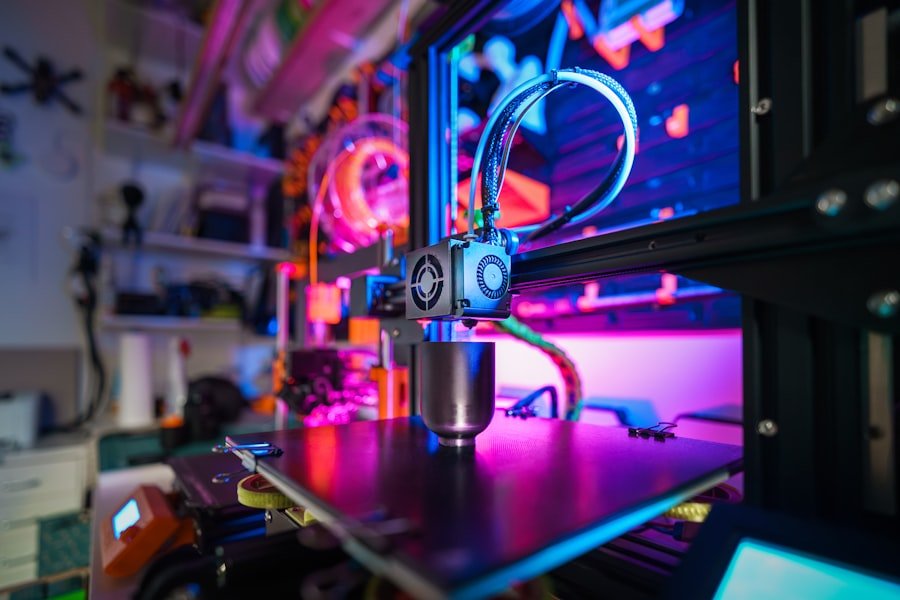

Increased Innovation and Creativity

Finally, 3D printing has been a catalyst for increased innovation and creativity across various industries. The ability to quickly translate digital designs into physical objects has empowered designers and engineers to push the boundaries of what is possible in product development. This has led to the creation of groundbreaking new products and solutions that were previously unattainable using traditional manufacturing methods.

Moreover, 3D printing has democratized access to manufacturing capabilities, allowing individuals and small businesses to bring their ideas to life without the need for large-scale production facilities or significant upfront investment. This has fostered a culture of entrepreneurship and creativity, leading to a surge in startups and small businesses leveraging 3D printing technology to disrupt established industries. Furthermore, 3D printing has democratized access to manufacturing capabilities, allowing individuals and small businesses to bring their ideas to life without the need for large-scale production facilities or significant upfront investment.

This has fostered a culture of entrepreneurship and creativity, leading to a surge in startups and small businesses leveraging 3D printing technology to disrupt established industries. In conclusion, additive manufacturing has transformed the way products are designed, developed, and produced across industries. The cost savings associated with 3D printing make it an attractive option for businesses looking to streamline their production processes and improve their bottom line.

The customization capabilities of 3D printing enable companies to offer unique products tailored to individual customer needs and preferences while also driving innovation and creativity in product development. Rapid prototyping with 3D printing empowers companies to quickly test and refine new product concepts based on customer feedback while reducing inventory costs through on-demand production models. Ultimately, 3D printing provides businesses with a competitive advantage by enabling faster time-to-market for new products and fostering increased innovation across various industries.