Lowering Production Costs: The Economic Benefits of 3D Printing

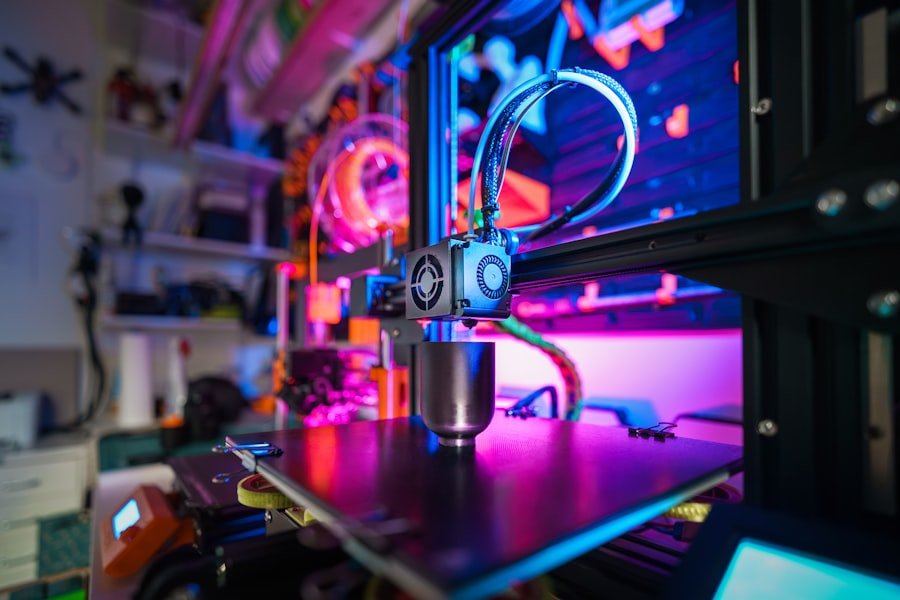

3D printing, also known as additive manufacturing, is a revolutionary technology that has been gaining traction in various industries over the past few decades. This innovative process involves creating three-dimensional objects by layering materials such as plastic, metal, or ceramics based on a digital model. The versatility of 3D printing allows for the production of complex and intricate designs that would be difficult or impossible to achieve using traditional manufacturing methods.

This technology has the potential to significantly reduce production costs, increase efficiency, and revolutionize the way products are made. The process of 3D printing begins with a digital model of the object to be produced, which is created using computer-aided design (CAD) software. The digital model is then sliced into thin layers, and the 3D printer builds the object layer by layer, using materials such as plastic, metal, or resin.

This layer-by-layer approach allows for precise control over the final product, resulting in high-quality and customizable items. 3D printing has the potential to disrupt traditional manufacturing processes by offering a more cost-effective and efficient way to produce goods. As the technology continues to advance, it is expected to have a profound impact on various industries, from aerospace and automotive to healthcare and consumer goods.

Reducing Material Costs with 3D Printing

Reducing Material Waste and Costs

One of the key advantages of 3D printing is its ability to reduce material waste and costs. Traditional manufacturing processes often result in a significant amount of material being wasted during production. In contrast, 3D printing only uses the exact amount of material needed to create the object, minimizing waste and reducing material costs.

Benefits for Industries with Expensive Materials

This is particularly beneficial for industries that rely on expensive or scarce materials, such as aerospace and medical device manufacturing. Furthermore, 3D printing allows for the use of recycled materials, further reducing costs and environmental impact. By using recycled materials in the printing process, companies can lower their production costs while also contributing to sustainability efforts.

Creating Lightweight and Durable Products

Additionally, 3D printing enables the creation of lightweight yet durable products, which can further reduce material usage and transportation costs. Overall, the ability to reduce material costs through 3D printing makes it an attractive option for companies looking to improve their bottom line while minimizing their environmental footprint.

Streamlining Production Processes with 3D Printing

In addition to reducing material costs, 3D printing can streamline production processes and lead to significant cost savings. Traditional manufacturing often involves multiple steps, including tooling, machining, and assembly, which can be time-consuming and labor-intensive. With 3D printing, many of these steps can be consolidated into a single process, saving time and reducing the need for manual labor.

This streamlined approach can result in faster production times and lower overhead costs. Furthermore, 3D printing allows for on-demand production, eliminating the need for large inventories and storage space. This just-in-time manufacturing approach can lead to significant cost savings by reducing inventory carrying costs and minimizing the risk of excess or obsolete inventory.

Additionally, 3D printing enables rapid prototyping and iteration, allowing companies to quickly test and refine designs without the need for expensive tooling or molds. This iterative approach can lead to faster product development cycles and ultimately reduce time-to-market, giving companies a competitive edge in their respective industries.

Lowering Labor Costs through Automation

Another significant benefit of 3D printing is its potential to lower labor costs through automation. Traditional manufacturing processes often require a significant amount of manual labor for tasks such as machining, assembly, and quality control. In contrast, 3D printing can automate many of these tasks, reducing the need for manual intervention and lowering labor costs.

This automation can also improve production consistency and quality by minimizing human error. Furthermore, 3D printing can enable the production of complex geometries and intricate designs that would be difficult or impossible to achieve using traditional manufacturing methods. This level of complexity can be achieved without the need for specialized tooling or skilled labor, further reducing labor costs and increasing production efficiency.

As 3D printing technology continues to advance, it has the potential to automate an increasing number of manufacturing processes, leading to further cost savings and productivity gains for companies across various industries.

Customization and Waste Reduction with 3D Printing

In addition to reducing material costs and streamlining production processes, 3D printing offers the unique ability to customize products and reduce waste. Traditional manufacturing often involves producing goods in large quantities, leading to excess inventory and waste from unsold or obsolete products. With 3D printing, companies can produce goods on-demand and customize them to meet specific customer needs, reducing waste and inventory carrying costs.

Furthermore, 3D printing enables the creation of complex and personalized designs that would be difficult or impossible to achieve using traditional manufacturing methods. This level of customization can lead to higher customer satisfaction and increased demand for products, ultimately driving revenue growth for companies. Additionally, 3D printing allows for the creation of spare parts and replacement components on-demand, reducing the need for large inventories and minimizing waste from obsolete parts.

Economic Benefits of Localized Manufacturing

Reducing Transportation Costs and Lead Times

Traditional manufacturing often involves long and complex supply chains, with goods being produced in one location and then transported to various markets around the world. This approach can lead to high transportation costs, long lead times, and supply chain disruptions. In contrast, 3D printing enables the production of goods locally, closer to the end consumer, reducing transportation costs and lead times.

Creating New Economic Opportunities

Localized manufacturing also has the potential to create new economic opportunities in local communities by enabling small-scale production and entrepreneurship. This approach can lead to job creation and economic growth in regions that may have been previously underserved by traditional manufacturing.

Mitigating Geopolitical Risks and Trade Uncertainties

Additionally, localized manufacturing can reduce the reliance on overseas production facilities, mitigating geopolitical risks and trade uncertainties. Overall, the economic benefits of localized manufacturing through 3D printing have the potential to reshape global supply chains and create new opportunities for businesses and communities around the world.

The Future of 3D Printing in Lowering Production Costs

In conclusion, 3D printing technology has the potential to significantly lower production costs across various industries by reducing material waste, streamlining production processes, lowering labor costs through automation, enabling customization, reducing waste, and promoting localized manufacturing. As the technology continues to advance and become more accessible, it is expected to have a profound impact on how goods are produced and distributed around the world. Companies that embrace 3D printing stand to benefit from increased efficiency, cost savings, and new opportunities for innovation and growth.

The future of 3D printing in lowering production costs is bright, with ongoing advancements in materials science, software development, and hardware capabilities driving further adoption and innovation. As companies continue to explore the potential of 3D printing in their operations, it is important to consider the broader implications of this technology on supply chains, labor markets, and economic development. By leveraging the unique capabilities of 3D printing, companies can position themselves for success in an increasingly competitive global marketplace while contributing to a more sustainable and efficient future for manufacturing.