3D printers

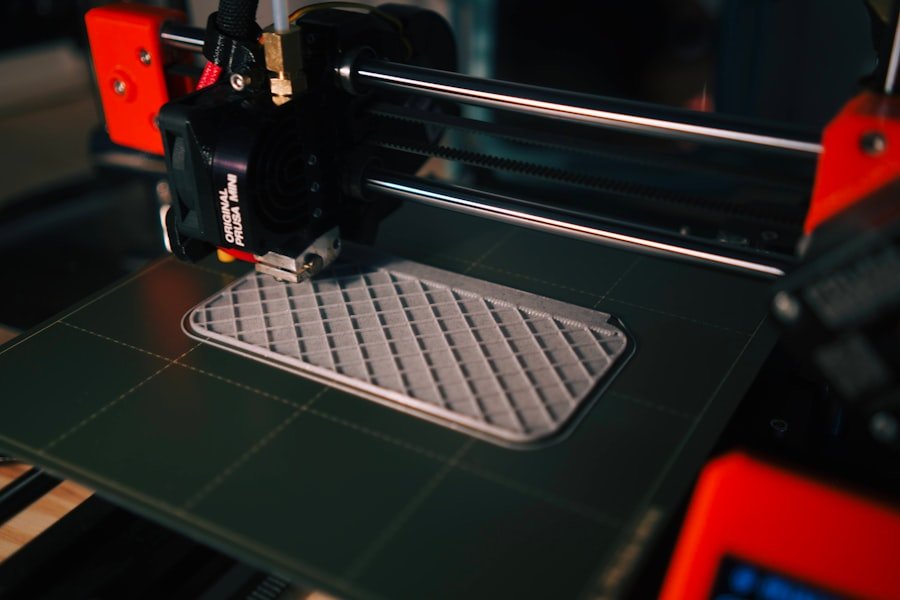

3D printing, also known as additive manufacturing, is a revolutionary technology that has been gaining momentum in recent years. It involves creating three-dimensional objects by layering materials such as plastic, metal, or ceramics based on a digital model. The process begins with a digital design created using computer-aided design (CAD) software, which is then sliced into thin horizontal cross-sections. These slices are sent to the 3D printer, which then builds the object layer by layer, fusing the material together to create the final product.

The concept of 3D printing was first introduced in the 1980s, but it wasn’t until the early 2000s that the technology became more accessible and affordable for commercial and personal use. Since then, 3D printing has evolved rapidly, with advancements in materials, printing techniques, and the range of objects that can be produced. Today, 3D printing is used in various industries, including aerospace, automotive, healthcare, and consumer goods. Its potential to revolutionize manufacturing and disrupt traditional production methods has made it a topic of great interest and investment.

The Advantages of 3D Printing

One of the key advantages of 3D printing is its ability to create complex and customized objects with intricate designs that would be difficult or impossible to produce using traditional manufacturing methods. This level of customization is particularly valuable in industries such as healthcare, where 3D printing is used to create patient-specific medical implants, prosthetics, and surgical guides. The ability to tailor products to individual needs can lead to better outcomes for patients and improved efficiency in healthcare delivery.

Another advantage of 3D printing is its potential to reduce waste and energy consumption compared to traditional manufacturing processes. With traditional methods, excess material is often cut away from a larger block or sheet, resulting in significant waste. In contrast, 3D printing only uses the exact amount of material needed to create the object, minimizing waste and reducing the environmental impact. Additionally, 3D printing can be more energy-efficient, as it eliminates the need for large-scale factories and transportation of finished products.

The Limitations of 3D Printing

While 3D printing offers many advantages, it also has its limitations. One of the main challenges is the limited range of materials that can be used in the printing process. While there has been significant progress in developing new materials for 3D printing, the range is still relatively narrow compared to traditional manufacturing methods. This can restrict the types of products that can be produced using 3D printing and limit its application in certain industries.

Another limitation of 3D printing is its speed and scalability. While 3D printing is ideal for creating small batches of customized products, it is not yet as efficient as traditional manufacturing methods for mass production. The time it takes to print each layer and the overall size of the object can limit the speed at which products can be produced. Additionally, the cost of 3D printing can be prohibitive for large-scale production, making it less competitive in industries where cost efficiency is a priority.

Applications of 3D Printing in Various Industries

The versatility of 3D printing has led to its adoption in a wide range of industries. In aerospace, 3D printing is used to produce lightweight components with complex geometries that are difficult to achieve using traditional methods. This can lead to significant weight savings in aircraft and spacecraft, resulting in improved fuel efficiency and performance. In healthcare, 3D printing is used to create patient-specific implants, prosthetics, and medical devices that are tailored to individual anatomy, leading to better patient outcomes.

In the automotive industry, 3D printing is used for rapid prototyping and producing custom parts for vehicles. This allows for faster design iterations and customization options for customers. In the consumer goods industry, 3D printing is used for creating unique and personalized products, such as jewelry, fashion accessories, and home decor items. The ability to customize products on-demand can lead to new business models and opportunities for small-scale manufacturers.

How 3D Printing is Revolutionizing Manufacturing

3D printing is revolutionizing manufacturing by enabling decentralized production and on-demand manufacturing. With traditional manufacturing methods, products are typically produced in centralized factories and distributed through supply chains to reach consumers. In contrast, 3D printing allows for localized production, where products can be manufactured closer to the point of consumption. This can lead to shorter lead times, reduced inventory costs, and lower transportation emissions.

Additionally, 3D printing is enabling new design possibilities and product innovations that were previously not feasible with traditional manufacturing methods. The ability to create complex geometries and lightweight structures opens up new opportunities for product optimization and performance improvements. This has implications for industries such as aerospace, automotive, and consumer goods, where lightweight and high-performance products are highly valued.

The Future of 3D Printing Technology

The future of 3D printing technology holds great promise for further advancements and widespread adoption. As materials science continues to evolve, we can expect to see a broader range of materials suitable for 3D printing, including advanced composites and bio-compatible materials for medical applications. This will expand the potential applications of 3D printing across various industries and enable the production of more complex and functional products.

In addition to materials advancements, improvements in printing speed and scalability will be crucial for expanding the use of 3D printing in mass production. Innovations in printing technologies and processes will likely lead to faster and more cost-effective production methods that can compete with traditional manufacturing on a larger scale. Furthermore, advancements in software tools and design optimization will enable more efficient use of materials and better integration with existing manufacturing processes.

The Impact of 3D Printing on Society

In conclusion, 3D printing technology has the potential to have a profound impact on society by transforming how products are designed, manufactured, and distributed. Its ability to create customized products, reduce waste, and enable decentralized production has implications for various industries and consumer markets. While there are still limitations and challenges to overcome, the continued advancements in materials, speed, and scalability are driving the widespread adoption of 3D printing across different sectors.

As 3D printing technology continues to evolve, we can expect to see new business models emerge, innovative product designs, and improved sustainability in manufacturing processes. The impact of 3D printing on society will extend beyond industry applications to include healthcare advancements, consumer empowerment through customization options, and environmental benefits from reduced waste and energy consumption. Overall, 3D printing has the potential to revolutionize manufacturing and reshape our relationship with products in the years to come.